Grain-Handling Systems in the Canadian Prairies

While oil may be considered the “prairie gold,” grain and the systems that delivered it to families across the world have staked claim to that title for much longer.

Better grain handling in Alberta means better profits for farmers, meals for Canadians, and a stronger economy for everyone.

The history of grain handling systems in the prairies goes back as far as the establishment of Canada itself, and the story is tied closely to those of the railroad, the first and second world wars, and even political espionage.

While Flynn Bros. Projects is proud to be a part of the ongoing evolution of farmers feeding Canadian and international families. We hope today to take a look at the history that led us to the innovations we custom-build today for farms like those around our home of Morinville, Alberta. Or, experience our expertise in action with a free consultation.

Early Canadian Agriculture and Exports

The establishment of the CN railway meant that for the first time, large-scale shipments of grain were possible and economically viable for overseas transportation. Between 1905 and 1910, the first elevator companies were established by farmers across the prairies.

The Grain Growers’ Grain Company, the Saskatchewan Co-operative Elevator Company and the Alberta Farmers’ Co-operative Elevator Company each came to make their home in central Canada and were instrumental in formulating The Canada Grain Act in 1912. This established the Canadian Grain Commission—a group focused on grain quality and developing grain varieties of superior quality and visually distinguishable characteristics.

With new agricultural products grown and ready to deliver, grain handling systems were poised to take over the now rail-connected Canadian landscape—up to and including supreme efforts during wartime measures to keep the Canadian people fed.

How “Prairie Sentinels” Spread Across the Prairies

Moving grain used to be a labour-intensive task done entirely by hand. Besides being slow and back-breakingly difficult, it was not a scalable operation as more grain being produced and delivered meant more hours spent loading and unloading by hand.

To take advantage of the new connections across Canada (and the land they freely leased to help speed up the development of depots/grain elevators), The Canadian Pacific Railway (CPR) began eyeing up larger, vertical warehouses that could take advantage of how grain acts closely to a fluid when in motion. As a result, a series of purpose-built chutes, conveyors, elevators, and “legs” were designed and implemented across the prairies. The uniform shape of these structures (function over form entirely) came to dominate the unadorned prairie skylines. It became a symbol of the economic growth driven by local farmers.

As complex laws regarding cross-breeding, import and export, and grain marketing evolved (culminating in the signing of NAFTA in 1993), Albertan, Manitoba, and Saskatchewan farmers were finally protected and enabled to pursue the choices that made their farms as profitable as possible.

Modern Grain Handling Systems and Custom Builds

Today, in an era of high transportation costs and economic uncertainty, grain storage has become increasingly important for operations of all scales.

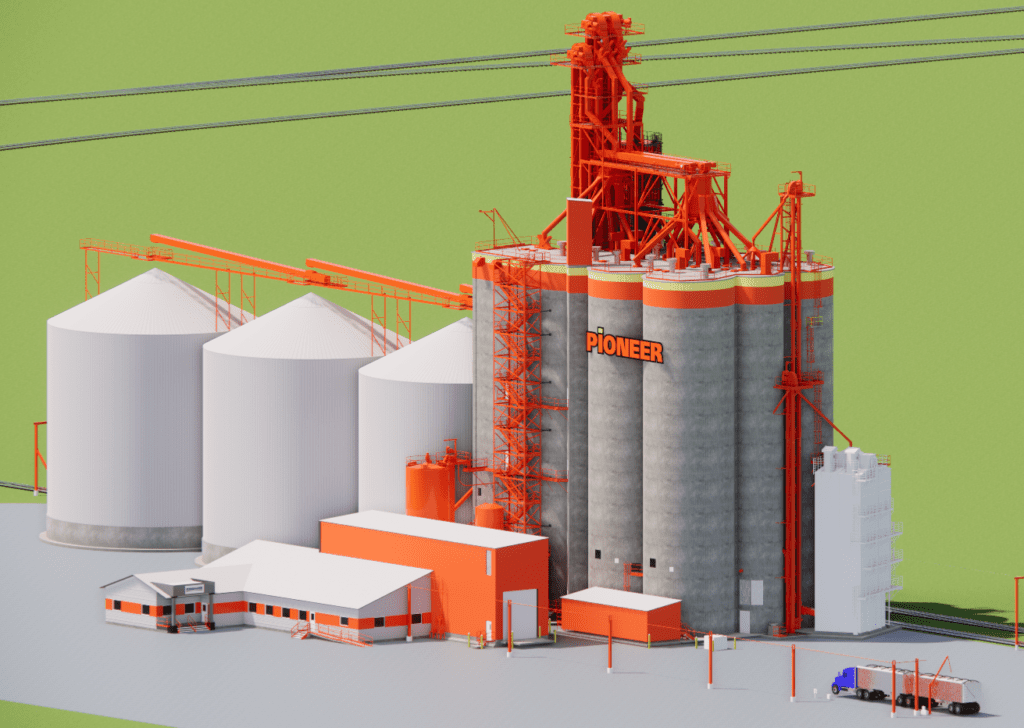

Custom-built grain storage equipment, transportation solutions, and high-performance structures allow grain handlers to make the right decisions when it comes to storing, managing, and selling the harvest. With considerations given to structural stability, heat management, pest control, and more, every modern piece of equipment brings with it decades of innovation gained as the prairies were sowed and harvested year after year.

Custom Grain Handling Systems With Flynn Bros. Projects

At Flynn Bros. Projects, you can trust that our experienced Millwrights and Welders are experts in the field. We are committed to doing the job right and use our own specially trained crew and custom equipment to deliver precisely what your agricultural operation needs.

You will not find a cookie-cutter solution with our grain bins but a customized grain storage system developed through collaboration and industry experts. Our expertise means that we can build you additional storage to handle 590,000 bu of grain or install all the grain handling equipment.

Whatever your project needs—we can deliver. Contact us today for a free consultation and to begin your next agricultural operations expansion confidently.

Stay Connected with Us!

Follow us on our social media channels to get the latest updates, exclusive offers, and behind-the-scenes content. Join our community and be part of the conversation!