Concrete piles and foundations | Bin jacking | Corrugated galvanized steel grain storage bins | Smooth wall steel storage bins | Hopper bottom bins | Conveyor tie-ins to existing facilities

Westlock, AB

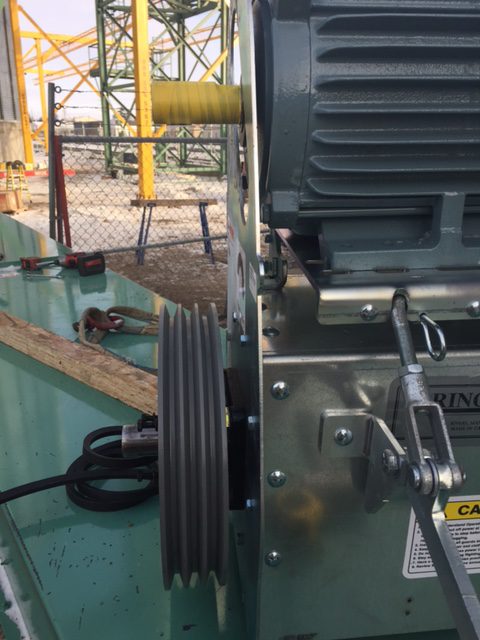

Westlock Terminals Grain Cleaner

Project Outline

The Westlock terminals facility wanted to add Grain cleaning capabilities which included two gravity cleaners, support tower, and inspection platform, along with 2 grain bins the first being a 21 foot diameter by 60 foot tall Brock E-Series hopper bottom for storing grain prior to cleaning and the second being a 14 foot diameter by 30 foot tall smooth wall Meridian bin for storing the chaff after cleaning.

- Included installation of Multiple Nordstrong Chain conveyors

- Included installation of 2 Nordstrong Bucket elevators

- Included cast in-place concrete foundations for bins, equipment and towers.

Project Challenges

The existing facility had very limited space for the new equipment. The project required modifications to 4 existing bins, including removal of the existing conveyance, filling the existing aeration and unload trenches in bin floors with concrete, then adding raised floors with a new aeration flooring, and installing U-Trough bin sweeps.

- Facility stayed operational during construction.

Project Successes

There were very minimal deficiencies and all were resolved quickly and the systems function as required. The client received their desired outcome at the end of the project.

PROJECT SPECIFICATIONS

Completion Date: December, 2016

END USE

Westlock Terminals Operations

PROJECT SIZE

Roughly 80’ wide by 160’ long

COMPLETION DATE

October 28, 2022

PROJECT DELIVERY METHOD

Shop fabrication, Vendor supplied equipment, on site construction and commissioning

COLLABORATORS

Nordstrong Equipment, BJD Electrical, LV Controls, Rock Solid Concrete

GET A FREE QUOTE FOR YOUR

Grain Handling Systems

Stay Connected with Us!

Follow us on our social media channels to get the latest updates, exclusive offers, and behind-the-scenes content. Join our community and be part of the conversation!